Tale of a Simple Pressure Switch

Here in Cameroon, we operate a helicopter program to serve areas where access is very difficult.

Recently, Jeff Johnson, a JAARS helicopter check pilot, came from the United States to give Mark Spangler, our only helicopter pilot in country, his periodic required flight checks.

They had completed half the required flying before the weekend, but on Monday morning during preflight inspection, they discovered a fuel leak coming from a pressure switch. Unfortunately, we didn’t have a replacement in stock, and, until the defective switch was replaced, they were grounded.

One simple part needed—but not a simple task to get it.

The pressure switch was definitely an AOG situation, ‘aviation speak’ for Aircraft on the Ground: The aircraft was grounded until we obtained a replacement pressure switch. In the United States, overnight shipping takes care of most AOG situations. The aircraft is soon back in the air. But we had to deal with an AOG order in the middle of Africa—overnight shipping was not an option.

With Jeff scheduled to leave in a week, an eight-month sea shipment of the part wasn’t practical. Sometimes people coming to Cameroon can bring extra luggage, and we pay the extra charges in order to get things faster. Unfortunately, no one was scheduled to come from the United States in the next week. Express carriers deliver to Cameroon, but it normally takes a week to get the package in country and then up to two weeks to complete the paperwork to get the package released.

Then a new possibility opened up. A lady was scheduled to come from Switzerland the following Saturday. I checked on the Internet for shops in Switzerland. After three calls I found one that had the switch in stock. I quickly emailed the lady, asking if she would be willing to bring the part with her. When I didn’t get a response right away, I had the parts company ship the switch to my in-laws in another area of Switzerland, thinking that, if she were not willing to carry it, they could send it by express carrier.

The lady agreed, but there wasn’t time for my in-laws to mail it to her address, so they drove two hours to give her the part before her flight. At the suggestion of a co-worker, I asked her to hand carry the switch, rather putting it in her checked luggage.

I had arranged for a taxi to pick her up at the airport, take her home, and then bring me the switch. Her flight arrived late … and they had lost her checked luggage. Was I glad that she had that switch in her hand carry! The switch finally arrived at my house at 11:15 p.m.

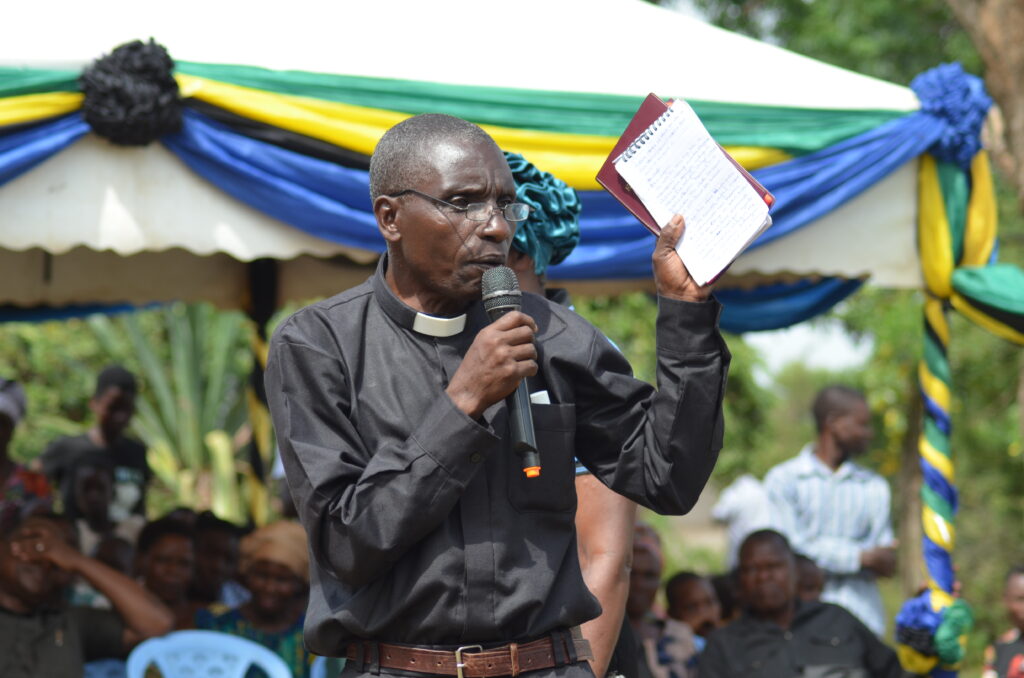

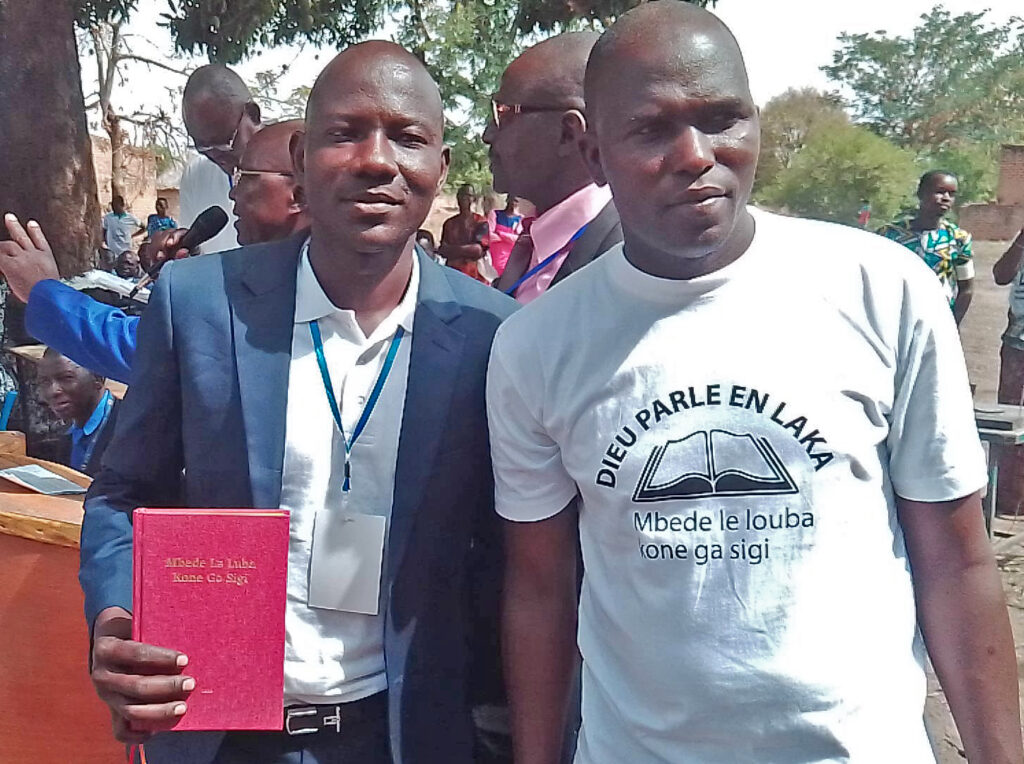

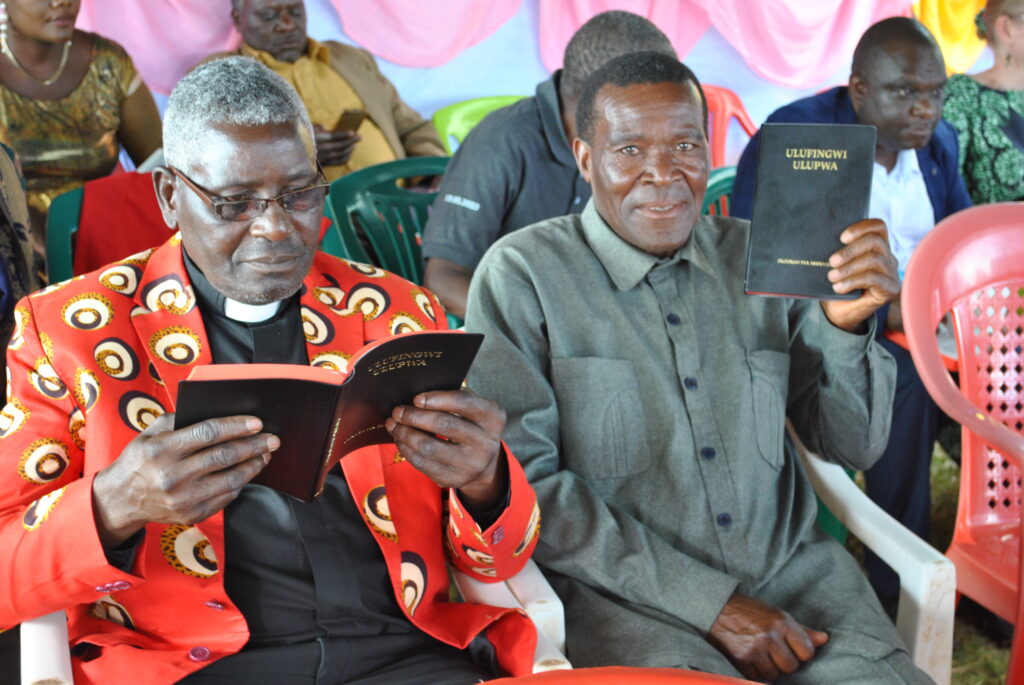

At 6:30 the next morning I flew the Cessna 207 Soloy from Yaounde to Banso to deliver and install the part. As a side benefit, Efi Tembon, the Director of CABTAL (Cameroon Association for Bible Translation and Literacy), rode along to meet with a local leader preparing for a Bible dedication. We arrived about 8 a.m., installed the pressure switch, and tested it. It worked with no problems! And Jeff and Mark immediately finished the training.

After the training flight Mark flew to a remote village to pick up Bruce Cox, a translator, and take him to one of the seminaries where he was scheduled to teach a course beginning the next morning. Meanwhile, Jeff and I flew about 15 minutes to Mbingo, a mission hospital, where we picked up a missionary and her son, Sam, who had been treated for a broken nose. We were soon on our way back to Yaounde, landing about 2:30 p.m.—in time for Jeff to make his flight back to the United States.

Small part—big impact! Mark received his required training; Jeff made his international flight; Efi traveled 90 minutes by air rather than 10 hours by road; Bruce taught as scheduled in the seminary; and Sam was back home in time to go to school Monday morning. That was the real value of the $90 pressure switch!